A Comprehensive Guide to Lifting Slings Safety

Introduction

Lifting slings have become an essential tool in various industrial settings across Australia, as they facilitate the support, lifting, and manoeuvring of heavy loads. Ensuring their safe and proper use prevents workplace accidents and promotes productivity. In this blog post, we will explore the best practices for using lifting slings in compliance with Australian laws, including inspection regulations, and how to assess their serviceability.

Understanding Lifting Slings

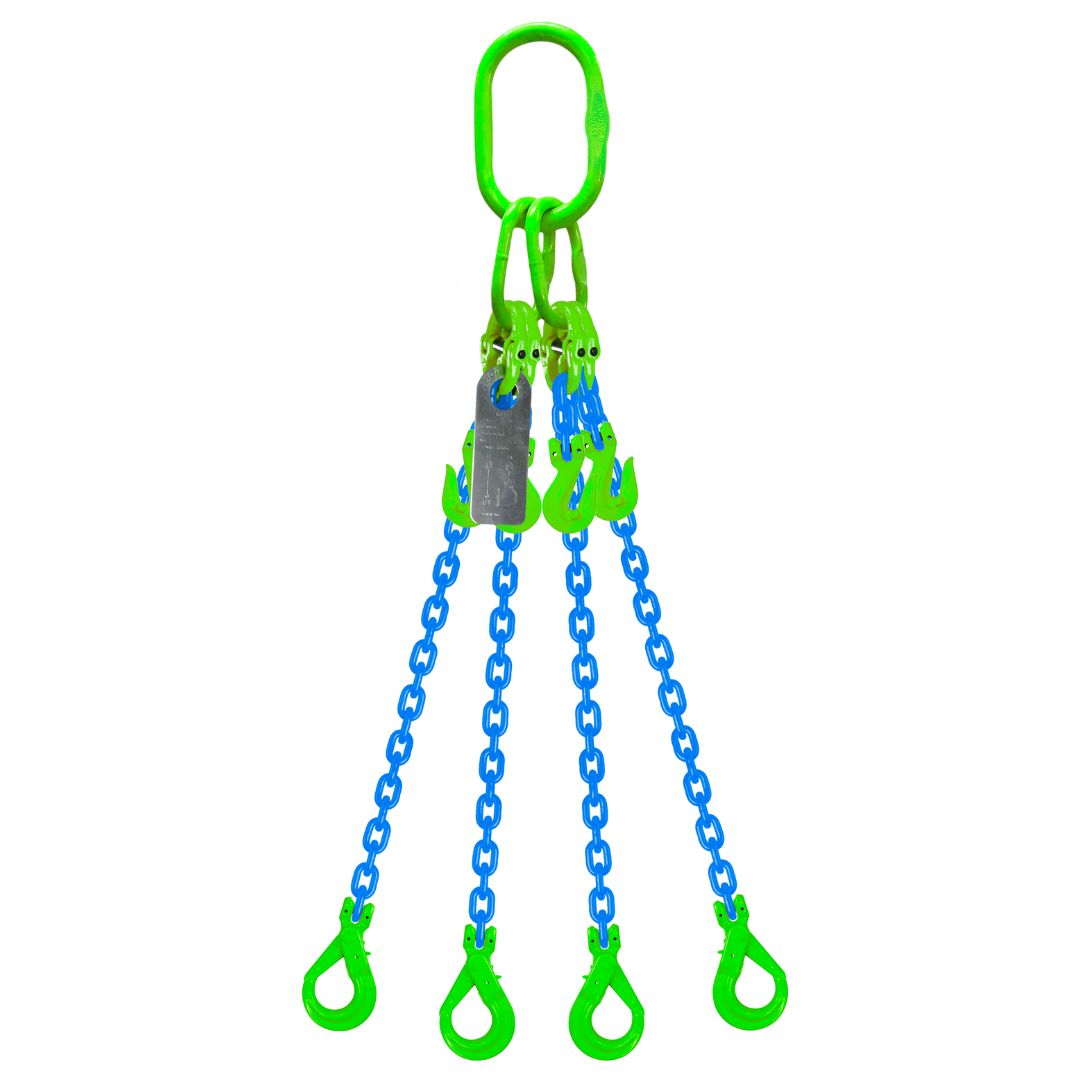

Lifting slings are flexible and adaptable tools that facilitate the support, lifting, and manoeuvring of heavy loads in numerous applications, from construction to manufacturing and beyond. They come in various materials, such as wire rope, chain, synthetic fibre, or metal mesh. Selecting the correct type of sling is crucial, as it depends on load characteristics, environmental conditions, and specific lifting requirements.

Safe Use of Lifting Slings in Australia

To ensure the safe use of lifting slings in Australia, it is essential to adhere to the guidelines set out in the Australian Standard AS 4497 (Round slings - Synthetic fibre), AS 3775 (Chain slings for lifting purposes), AS 1666 (Wire-rope slings), and AS 1666.1 (Product specification). Key safety measures include:

- Selecting the appropriate sling: Choose the right type, material, and sling capacity for the load and lifting conditions.

- Inspecting the sling: Perform a thorough visual inspection before each use. Check for any signs of wear, damage, or deformities.

- Rigging the sling correctly: Use the correct hitch type and ensure that the sling is rigged securely around the load.

- Maintaining a safe lifting angle: Avoid sharp angles and ensure the sling evenly supports the load.

- Monitoring the lift: Always have a competent person supervising the lift and ensure that proper communication channels are in place.

Lifting Sling Inspection Regulations in Australia

Adhering to inspection regulations and guidelines outlined in the relevant Australian Standards and Work Health and Safety (WHS) regulations is crucial for the safe and compliant use of lifting slings in Australia. The frequency and scope of inspections depend on several factors, including usage, environmental conditions, and the type of sling being used. According to the WHS regulations and Australian Standards, lifting slings should undergo the following types of inspections:

- Pre-use inspection: Conduct a visual inspection by the sling operator before each use to identify any visible defects or damage.

- Periodic inspection: Perform a more detailed inspection by a competent person at regular intervals determined by the type of sling, its usage, and environmental conditions. For example, AS 3775.2 recommends that chain slings used in regular service should be inspected at least every three months, while those used in severe service should be inspected monthly.

- Special inspection: If the sling has been subjected to an incident that may have affected its integrity, such as an overload, shock load, or contact with corrosive substances, a special inspection should be performed by a competent person.

A comprehensive inspection should cover the following aspects:

- Visual examination: Inspect for cuts, abrasions, excessive stretching, heat damage, or signs of chemical exposure.

- Tactile examination: Feel for inconsistencies, such as broken wires or links, embedded particles, or changes in the sling's texture.

- Load capacity and identification: Ensure the sling's rated capacity and identification tags are legible and have not been tampered with.

- Hardware inspection: Examine any associated hardware, such as hooks, shackles, or rings, for signs of wear, deformation, or cracks.

- Documentation: Maintain accurate inspection records, including any repairs or modifications made to the sling.

Conclusion

Ensuring the safe use and serviceability of lifting slings is crucial for maintaining a safe working environment and complying with Australian regulations. By following the best practices outlined in this guide and adhering to the inspection regulations as per the relevant Australian Standards and WHS regulations, you can help prevent accidents, protect your employees, and prolong the service life of your lifting equipment. Regular inspections by competent personnel, appropriate documentation, and timely removal of damaged slings from service are vital components of a robust safety culture. Stay informed and prioritise safety to foster a productive, accident-free workplace in Australia.

Leave a comment