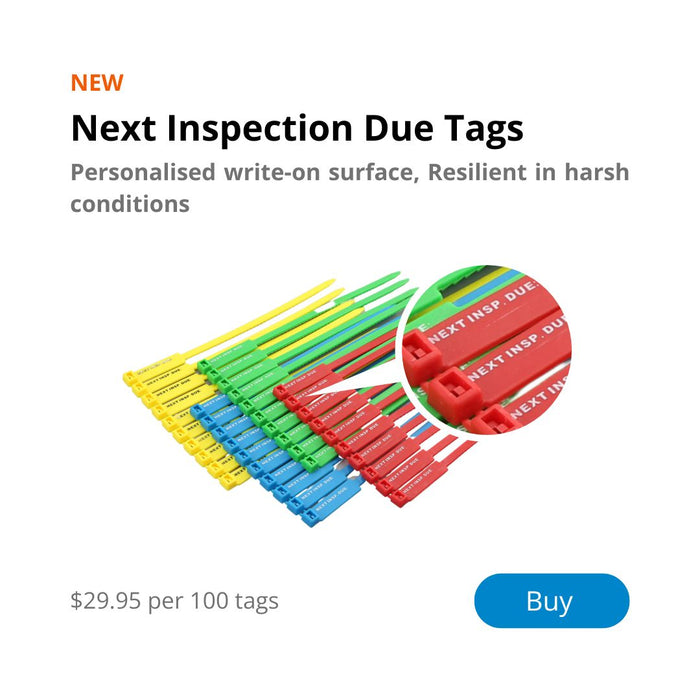

Next Inspection Due Tags

Online Only

Conveying & Hoisting Solutions does not have a storefront open to the general public. However, you may select the Click & Collect option at checkout. We'll notify you when its ready for pickup

Learn more

Product Description

Discover a New Standard of Safety with Our Next Inspection Due Tags

Experience a seamless blend of safety and convenience with our vibrant, user-friendly Next Inspection Due Tags. These aren't just ordinary tags - they're your ticket to a stress-free, safety-centric workspace.

Why Choose Our Next Inspection Due Tags?

Our premium quality tags aim to alleviate concerns about the inspection status of your safety equipment. Specifically designed for the lifting industry, our tags provide crucial, easily readable information about a range of equipment, including Lifting Gear, Lifting Shackles, Wire Rope, Safety Nets, Harnesses, and Eyebolts. Investing in our Next Inspection Due Tags isn't merely a purchase; it's a commitment to safety, assurance, and peace of mind.

Key Features of Our Next Inspection Due Tags

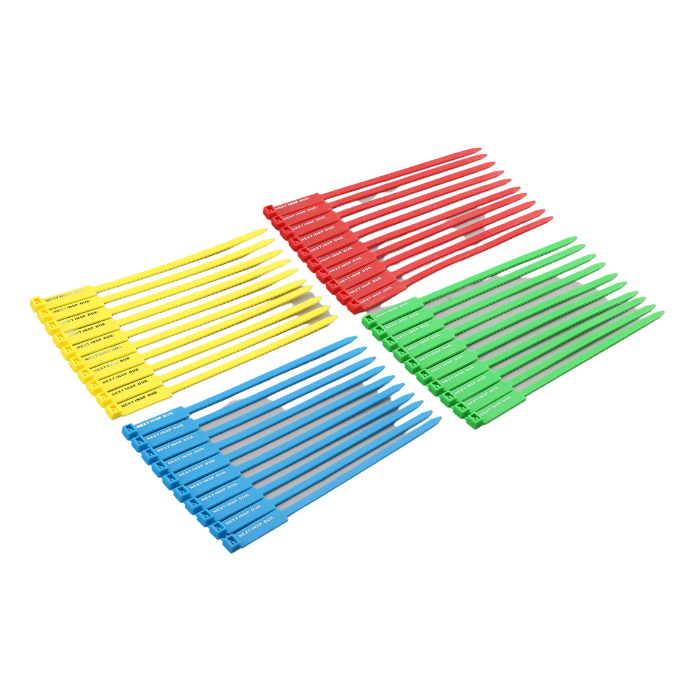

- Vibrant, attention-grabbing colours: Each tag is a masterpiece, crafted to captivate with an array of vivid colours, ensuring critical safety information never goes unnoticed.

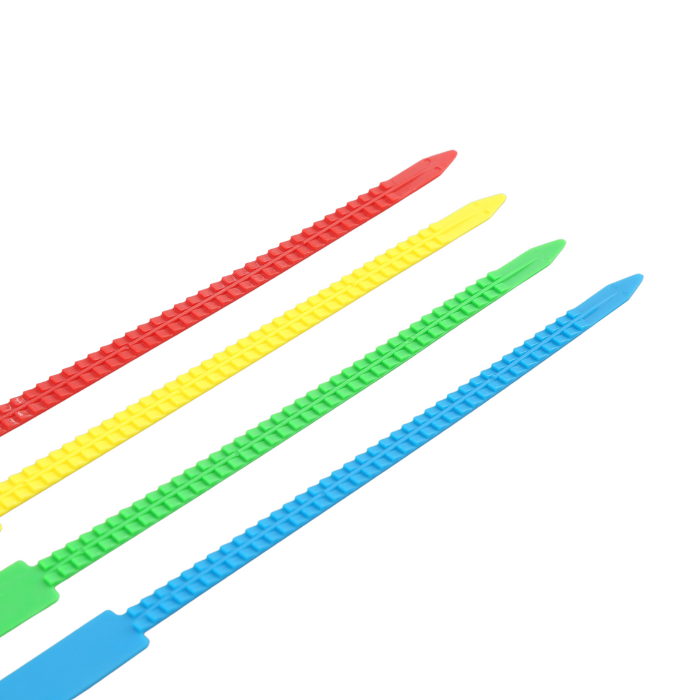

- Resilient in harsh conditions: Our tags are not only visually appealing but also durable enough to withstand the most challenging work environments.

- Personalised write-on surface: Each tag offers a dedicated space to jot down the last inspection date and any other essential details - just write, attach, and relax!

- Assorted colour options: With options including Blue, Green, Orange, Red, White, and Yellow, you can choose the colour that best suits your safety system.

- Packaging options: Available in packs of 100 or mixed packs of 40 (Blue, Green, Yellow, Red), so you can choose what best fits your needs.

Take Control of Your Safety Routine with Our Next Inspection Due Tags

Are you ready for a more streamlined, efficient safety routine? Harness the power of our Next Inspection Due Tags, your essential tool for maintaining a colour-coded safety system. Because we believe that safety should be personalised to your specific requirements.

Join the Safety Revolution Today

Become part of the safety revolution today with our Next Inspection Due Tags, your vibrant solution to ensuring a secure working environment. Remember, when you choose our Next Inspection Due Tags, you're not just buying a product - you're investing in a safer future.

Inspection Frequency

When Should Inspections Occur? The question of how often inspections should take place doesn't have a one-size-fits-all answer. First, let's define inspections, as there are two main categories commonly referenced in Australian Standards: in-service and periodic inspections.

In-service Inspections

An in-service inspection requires a visual check before each use. Before every lift, the user should closely examine the equipment, including slings, hooks, and lifting points, to make sure there's no substantial wear or damage and that the Working Load Limit (WLL) tags or markings are intact and legible. If any faults are detected, the equipment must be removed from service and evaluated by a qualified individual who will decide whether to use, fix, or discard it.

Periodic Inspections

These are more comprehensive inspections where the equipment is cleaned and checked in a well-lit place by a trained inspector with good eyesight. This is specifically outlined in standards like the Chain Sling standard. Adequate documentation of these inspections is also required.

The frequency of inspections may depend on various factors:

- The extent to which the item is used and the level of the load (e.g., whether it is consistently used at its working load limit)

- The environmental conditions where the equipment is used and stored, especially if exposed to dirt or corrosive elements

- Specific types of lifting gear that may be more likely to degrade quickly, such as slings made of synthetic fibers or certain wire rope slings with soft eyes, might necessitate more regular checks

The general guidelines for inspection frequencies, in accordance with Australian Standards, can be tailored by those in charge of lifting and rigging equipment. They must determine whether these guidelines are suitable for their particular circumstances or if a more rigorous inspection routine is warranted.

| Item | Standard | Frequency |

| Soft Slings/FWS | AS1353.2 | Slings shall be inspected by a competent person at intervals of service of not more than 3 months. |

| Chain Assemblies | AS3775.2 | Periodic inspection by competent person. Suggested 12 monthly intervals. |

| Lashing Chain | AS4344 | Regular inspection by the user. |

| Wire Rope Assemblies | AS1666 | Recommended periodic inspection by a competent person 12 monthly, subject to usage. |

| Lifting Clutches | AS3850 | A proof test using a load equal to 1.2 times the WLL shall be conducted and recorded at least 12 monthly intervals. |

| Lifting Beams | AS4991 | Lifting devices shall be inspected by a competent person at intervals specified by the manufacturer or by the competent person. Suggested 12 monthly. |

| Monorail/Gantry | AS1418.3 | Initial inspection not greater than 2 years (in first 6 years), then 12 monthly. At the time of commissioning only each hoist shall be proof loaded to 100% of its rated capacity AS1418.3, 1418.18. |

| Harnesses/Lanyards | Operator inspection before and after each use. Documented inspection 6 monthly by height safety equipment Inspector. | |

| Horizontal or vertical lifelines - Webbing or fibre ropes | Documented inspection 6 monthly by height safety equipment Inspector. | |

| Horizontal or vertical lifelines - Steel rope or rail | Frequency of inspection by height safety equipment Inspector as recommended by the manufacturer, a maximum of 5 yearly. Documented 12 monthly inspection in the absence of such recommendations. | |

| Anchors chemical & mechanical - If not secured with nut | Proof load yearly. Rating 15kN 1 person, 21kN 2 people. Must be documented. | |

| Anchors chemical & mechanical - Anchor nut secured | No proof load but structure needs to be tested or engineer certified. | |

| Type 1 Fall Arrestors | Rope grabs, lad safe, lifeline. Annual documented Inspection by height safety equipment Inspector. | |

| Type 2 Fall Arrestors | Self-retracting lifelines. 6 monthly documented inspection. Service as recommended by the manufacturer to a maximum of 5 years. 12 monthly in the absence of such recommendation. Completed by height safety equipment inspector. | |

| Type 3 Fall Arrestors | Self-retracting lifelines with winch. 6 monthly documented inspection. Service as recommended by the manufacturer to a maximum of 5 years. 12 monthly in the absence of such recommendation. Completed by height safety equipment inspector. |