Reliable Safety Anchor Solutions You Can Trust

Safety anchor points are the backbone of any fall protection system. At Conveying & Hoisting Solutions, we supply a wide range of certified anchor products — from roof safety anchors to webbing anchors — that meet AS/NZS 1891.4 standards and WHS Codes of Practice.

Our anchor solutions are:

- Pre-engineered and certified to Australian standards

- Durable and reliable under Sydney’s climate and building conditions

- Compliant with WHS regulations for safety audits

- Flexible — suited for temporary works like façade maintenance or long-term roof safety systems

Every anchor product is backed by compliance documentation, inspection schedules, and recertification reminders, so your safety system stays audit-ready year after year.

Contact us today to arrange a free consultation and ensure your site is equipped with certified, reliable safety anchors.

Why Choose Our Sydney Anchor Solutions?

When it comes to safety anchor points in Sydney, here’s why businesses trust us:

- Local expertise & compliance – We know WHS NSW laws, Sydney’s building codes, and site conditions.

- Proven track record – Every installation includes a compliance certificate, backed by 110 years of combined experience and 12,000 projects delivered.

- End-to-end service – From design to certification, all under one roof.

- Quality & traceability – Every anchor is load tested, labelled, and certified.

- Custom fit – Roof anchors, concrete anchors, or retrofit options — we adapt to your site.

- Ongoing support – Maintenance plans, annual recertification, and staff training included.

We’ve supported industries across Sydney, from construction sites to high-rise commercial buildings, with custom anchor solutions that protect workers and meet regulatory requirements.

How Often Should Anchor Points Be Inspected?

Safety anchor points must be inspected:

- Every 12 months

- After heavy use

- After an incident or repair

This ensures they remain safe and compliant with AS/NZS 1891.4 standards.

Can An Old Building Support New Anchor Points?

Yes. Most older buildings can support new safety anchor points once engineers assess roof type and substrate strength. If reinforcement is needed, customised anchorages are designed to keep the structure safe and compliant.

What is the Process for Installing Safety Anchor Points?

Our step-by-step approach:

- Site review & structural check

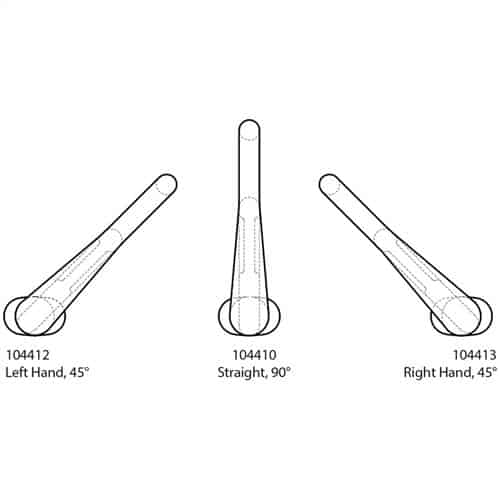

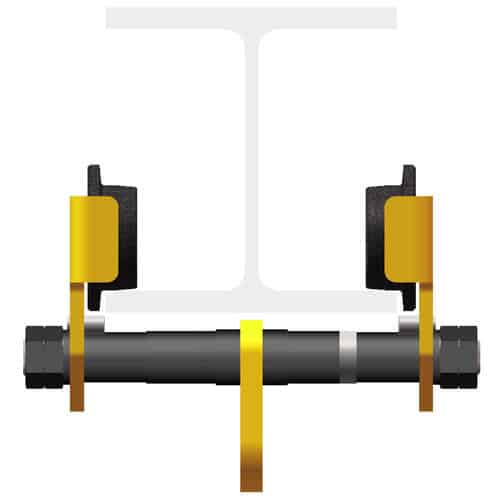

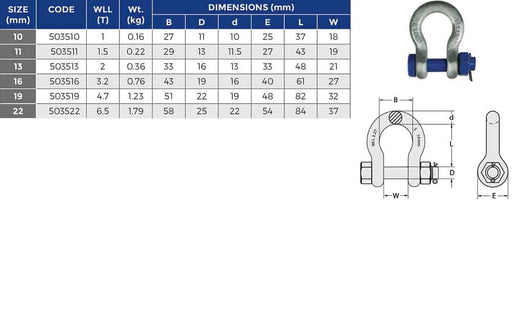

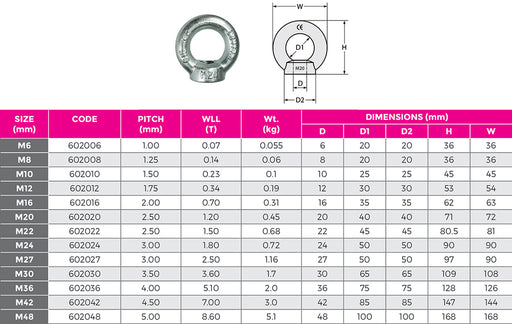

- Anchor design & selection

- Marking & layout for optimal coverage

- Mounting & fixing (mechanical or adhesive)

- Load testing & certification

- Labelling with test date, rating, and maintenance schedule

- Staff handover & training

This process guarantees your system isn’t just installed — it’s engineered, verified, and ready for safe use.

When Can You Use Safety Anchor Points?

Anchor points are essential for:

- Roof maintenance, HVAC, or solar panel work

- Façade cleaning or cladding inspections

- Building signage or antenna servicing

- Structural inspections at height

We recommend installing anchors during construction to cut retrofit costs, but our team also excels in upgrading older buildings with roof anchors and concrete anchor points.

How Conveying & Hoisting Solutions Helps with Safety Anchor Points

We provide seamless project delivery from start to finish:

- Consultation & survey – Assess roof, structure, and usage.

- Design & engineering – Select anchors that meet AS/NZS standards.

- Installation & certification – Completed by accredited technicians.

- Inspection & recertification – Annual testing and reporting.

- Support & training – Staff induction on safe use and inspection routines.

Don’t wait for a safety audit to highlight risks. Inquire today and ensure your building is fully compliant with Sydney WHS standards.